PEEK is mainly used when other plastics are no longer suitable because of their inadequate mechanical strength and, or, chemical resistance. For example, PEEK has much higher load carrying capability than PTFE (even highly reinforced grades). These attributes still hold at high temperatures. PEEK has a glass transition temperature of around 143°C and melts at approx. 343°C.

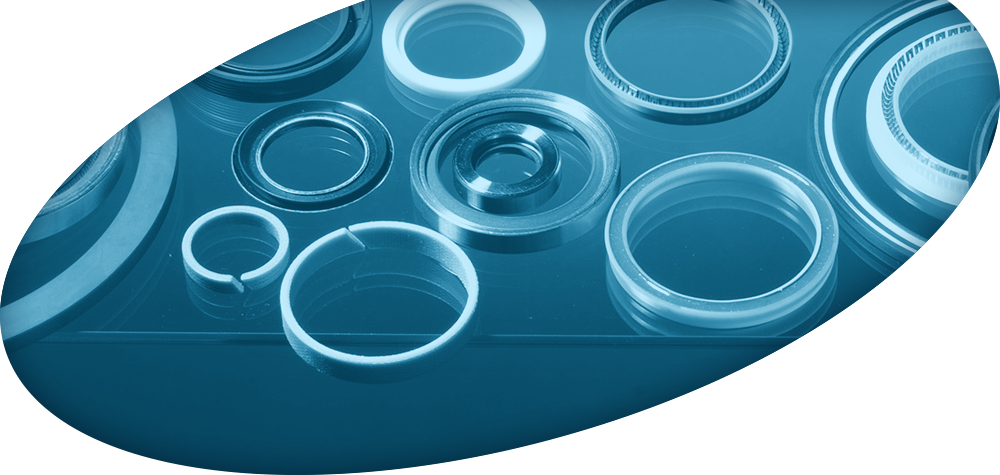

In sealing applications, PEEK is predominantly used for parts that prevent extrusion of rubber moulded seals and other components made out of lower strength thermoplastics.

PEEK is highly resistant to both organic and aqueous solvents. It is attacked by halogens and Brønsted and Lewis acids as well as by some halogenated compounds and aliphatic hydrocarbons at high temperatures. It dissolves completely in concentrate sulphuric acid at room temperature.

This family of thermoplastics is mainly characterised by:

- Excellent mechanical properties (high strength, high rigidity, low creep)

- Excellent dimensional stability

- Good chemical resistance (except with halogens and selected acids)

- Good resistance to hydrolysis

- Excellent temperature resistance (+250°C continuous with possible excursions to +300°C).