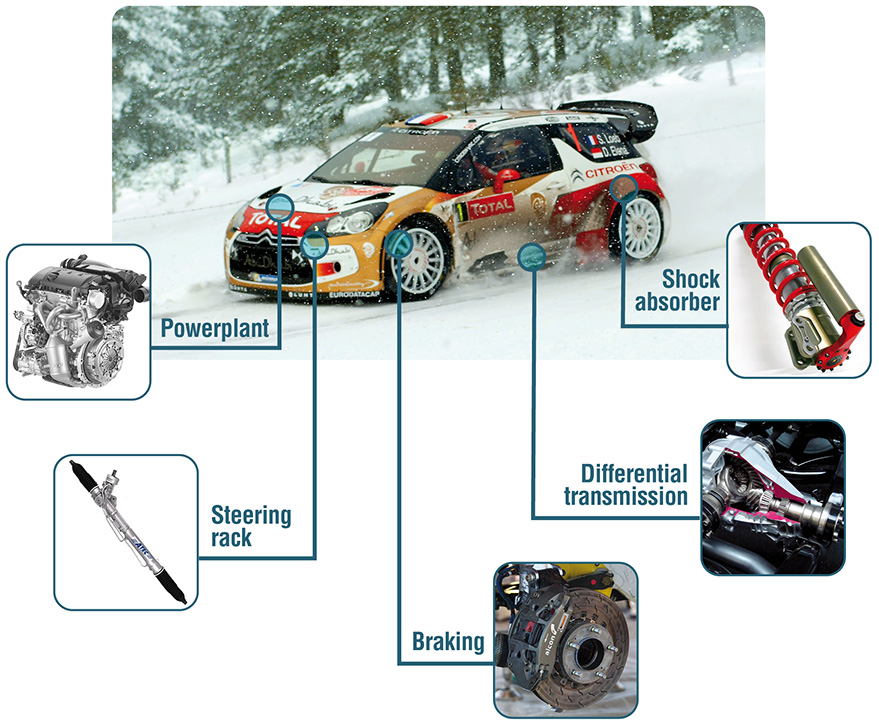

Repack-S experience and track record is 2nd to none when it comes to producing ultra reliable low friction – yet highly effective – sealing solutions for race engines (valve stems, crankshafts, lubrication & fuel pumps), KERS, sequential gearboxes, limited slip differentials, shock absorbers, steering racks and brake actuators.

Designing and manufacturing the most successful seals in Motorsport takes passion (we have plenty!) but also experience, a good measure of lateral thinking and a special understanding of important considerations such as the effects of linear or rotating speed, stiction, varying coefficients of friction, heat build-up, pressure fluctuations, vibration amplitudes and frequencies, and of course, tribology!

Reducing friction is critical in many applications. Lower friction helps reduce power consumption but it also leads to increased seal life in high revving systems. Repack-S has spearheaded the introduction of new innovative polymer filler technologies to reduce friction, improve resistance to heat and expand the scope for high-performance engineering polymers where previously impossible.

Seal manufacture – precision engineering technology

Obtaining long-term effective sealing with minimum friction requires precision manufacturing techniques to achieve high dimensional accuracy. Repack-S has invested in manufacturing and quality systems to ensure these tighter-than-normal tolerances are achieved. We manufacture in a temperature-controlled environment and are able to produce “blueprint” parts.

Seal testing – not all seals are created equal

Race components designers often don’t appreciate that the quality of base polymers can vary greatly dependent upon the manufacturer. Repack-S engineers rely on a dedicated test laboratory to simulate the performance of seals in use, ensuring performance as well as consistency objectives are met.

Repack-S sealing solutions include a range of proven seal designs: HPX®-Mono®, DANAFLEX®, DANAROTO®, DANAWING®, DANAGLIDE®, DANACAP® and DANASTEP®. All these solutions, when specified properly, offer highly effective, long-lasting and utterly reliable sealing performance.