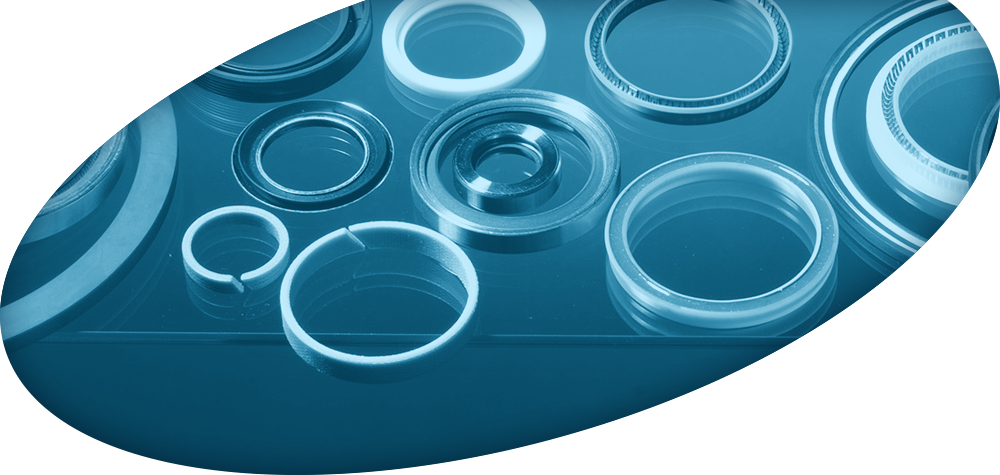

REPKOT® is used for bush bearings, thrust bearings, guide strips, wear rings, piston segments and other custom-designed machined parts that require low friction coefficient, high wear resistance and excellent load carrying capability.

REPKOT®’s friction properties can be further lowered with the addition of MoS2 and PTFE. In the presence of water, the coefficient of friction of REPKOT® is comparable to that of PTFE.

REPKOT®’s maximum resistance to compressive load is 414 N/mm2.

Typical REPKOT® attributes include:

- Self-lubricating

- High compression load resistance

- High wear and abrasion resistance

- Low humidity absorption

- Electrically insulating

- Vibration insulating

- Low density

- Non-toxic.

Please refer to our dedicated Technical Design Guide – in the downloadable brochure section – for more a detailed description of all REPKOT® characteristics, values and performance graphs.